Supporting copy for the Request Service

call out button.

Outstanding service is our goal

Serving Nationwide and Internationally 770-483-6000

POLISHING

Serving Nationwide and Internationally

770-483-6000

Serving Nationwide and Internationally

Call Us Today

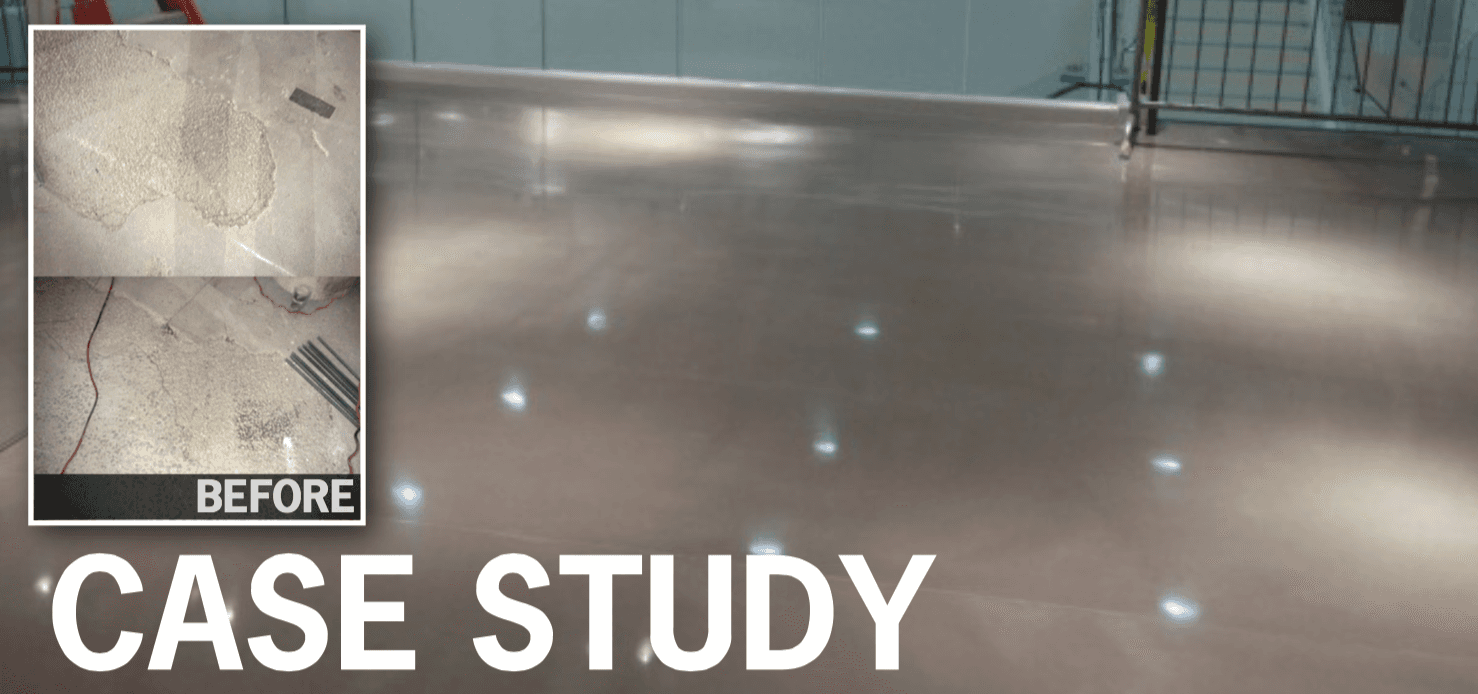

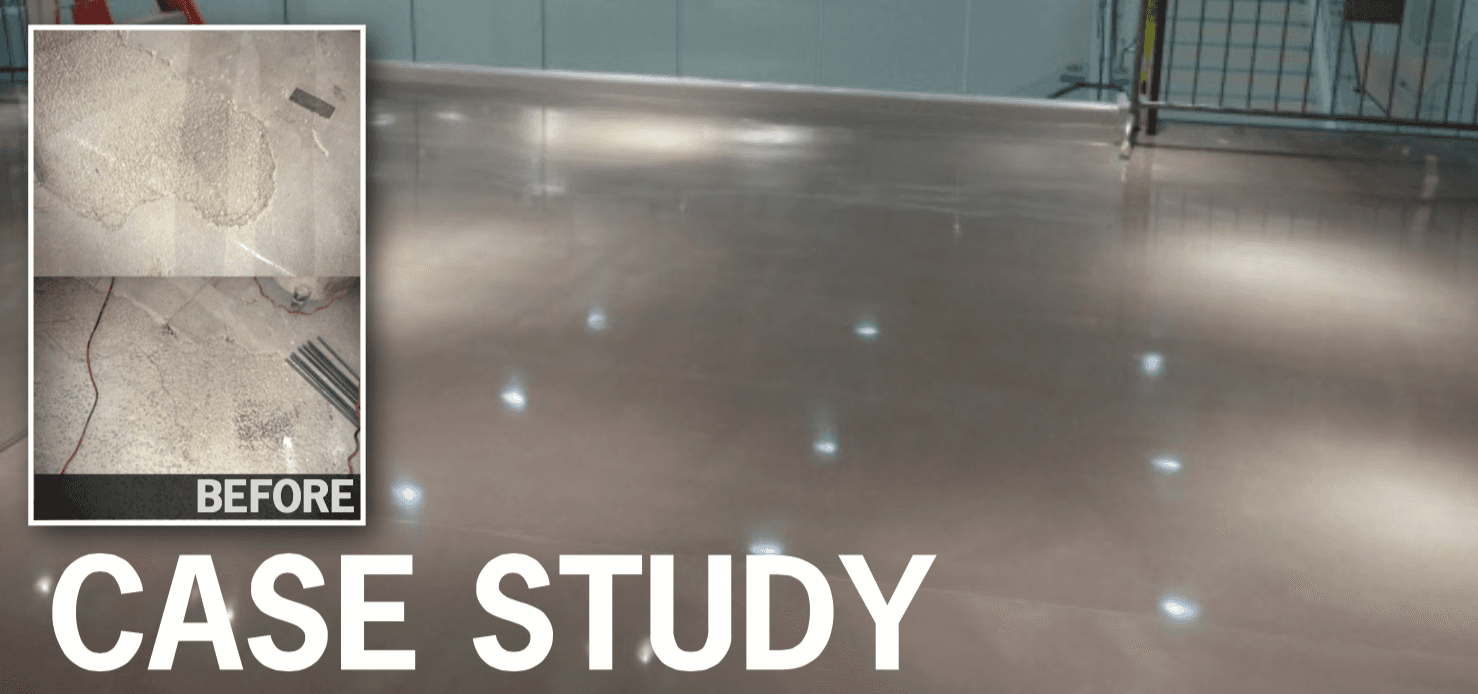

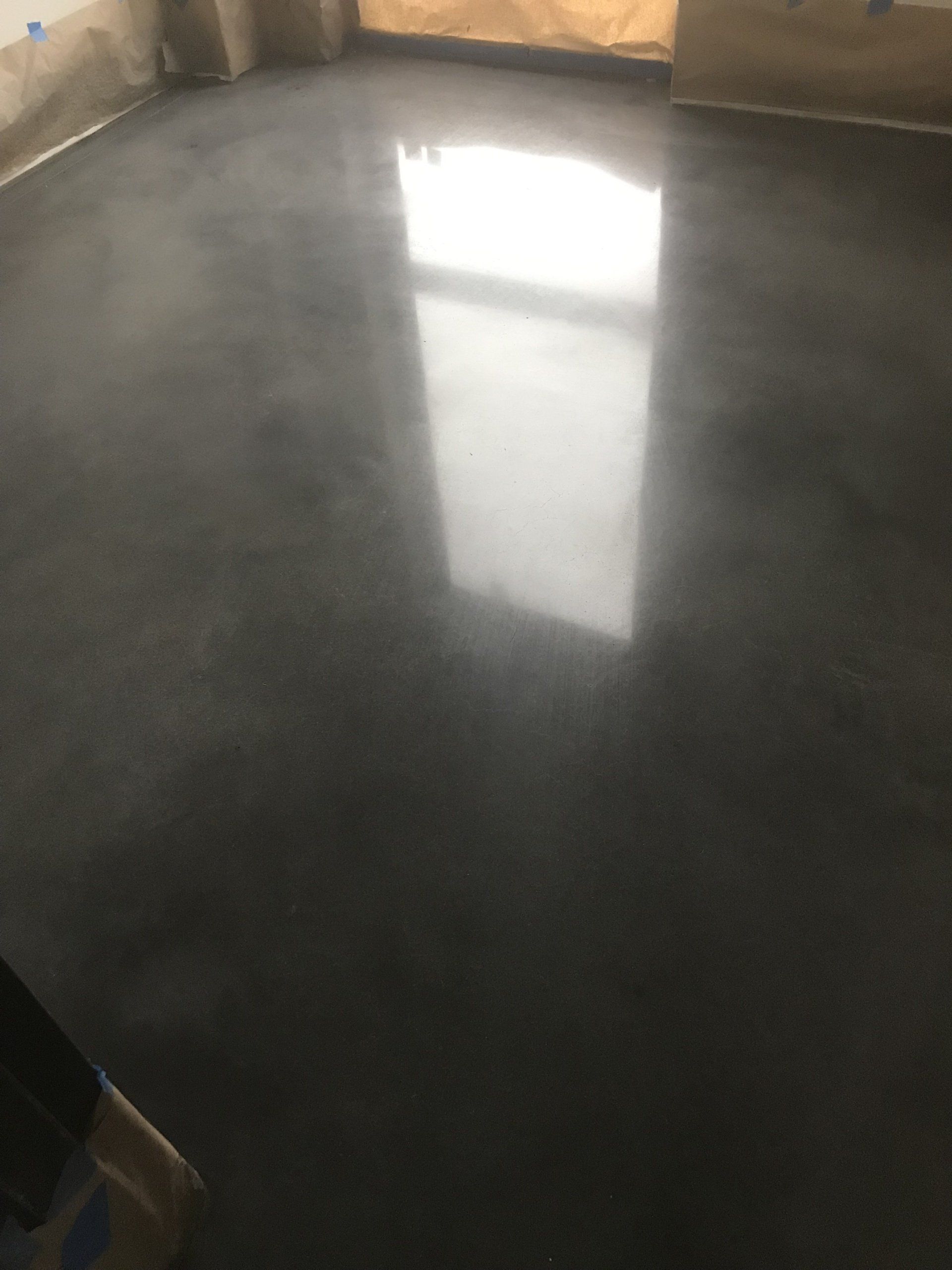

Polished Concrete Floors

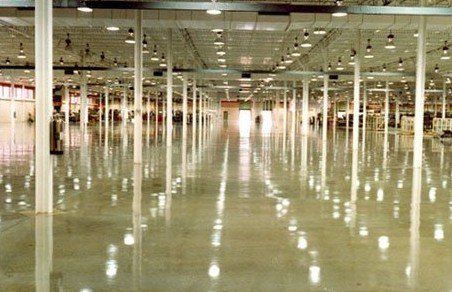

Polished concrete floors are some of the most durable, cost effective, and low maintenance flooring solutions available. Polished floors are ideal for retail, commercial, and industrial environments. Southeast Sealing, Inc. has many years of concrete polishing experience with projects of all sizes, and we can custom tailor a level of gloss to specifically meet the requirements of any facility.

HIGH-QUALITY CONCRETE FLOOR POLISHING:

Polished concrete is created by starting with coarse diamonds and grinding the slab, then repeating the polishing process multiple times with a series of finer and finer diamonds until the desired surface profile and gloss are obtained. We perform this work utilizing powerful electric orbital diamond grinding and polishing equipment. Our machinery is from top manufacturers such as SASE, Diamatic, Terco, and Hilti. We utilize a dry process and control dust with powerful vacuums equipped with HEPA filters. This eliminates slurry disposal issues associated with wet grinding.

During the polishing process we apply a liquid concrete hardener/densifier to the slab. This is a clear odorless solution with no or extremely low VOCs. It chemically reacts with the calcium hydroxide which is present in concrete floors and produces calcium silicate hydrate (C-S-H). Concrete floors are by nature a porous substance with microscopic canals leading to the surface. Our densifier penetrates deep within the slab and chemically reacts with the concrete. Consequently, there is no material vulnerable to peeling or delamination. The reaction creates C-S-H and increases the strength and hardness of the concrete floor.

After the final pass with the diamond floor grinding and polishing machines, we apply a penetrating stain resistant treatment. In addition to stain resistance, the treatment adds strength and creates abrasive resistance to protect the polished floor from wear. This environmentally friendly treatment is also colorless, odorless, and low VOC. This application is followed up with burnishing to heat set the protectant.

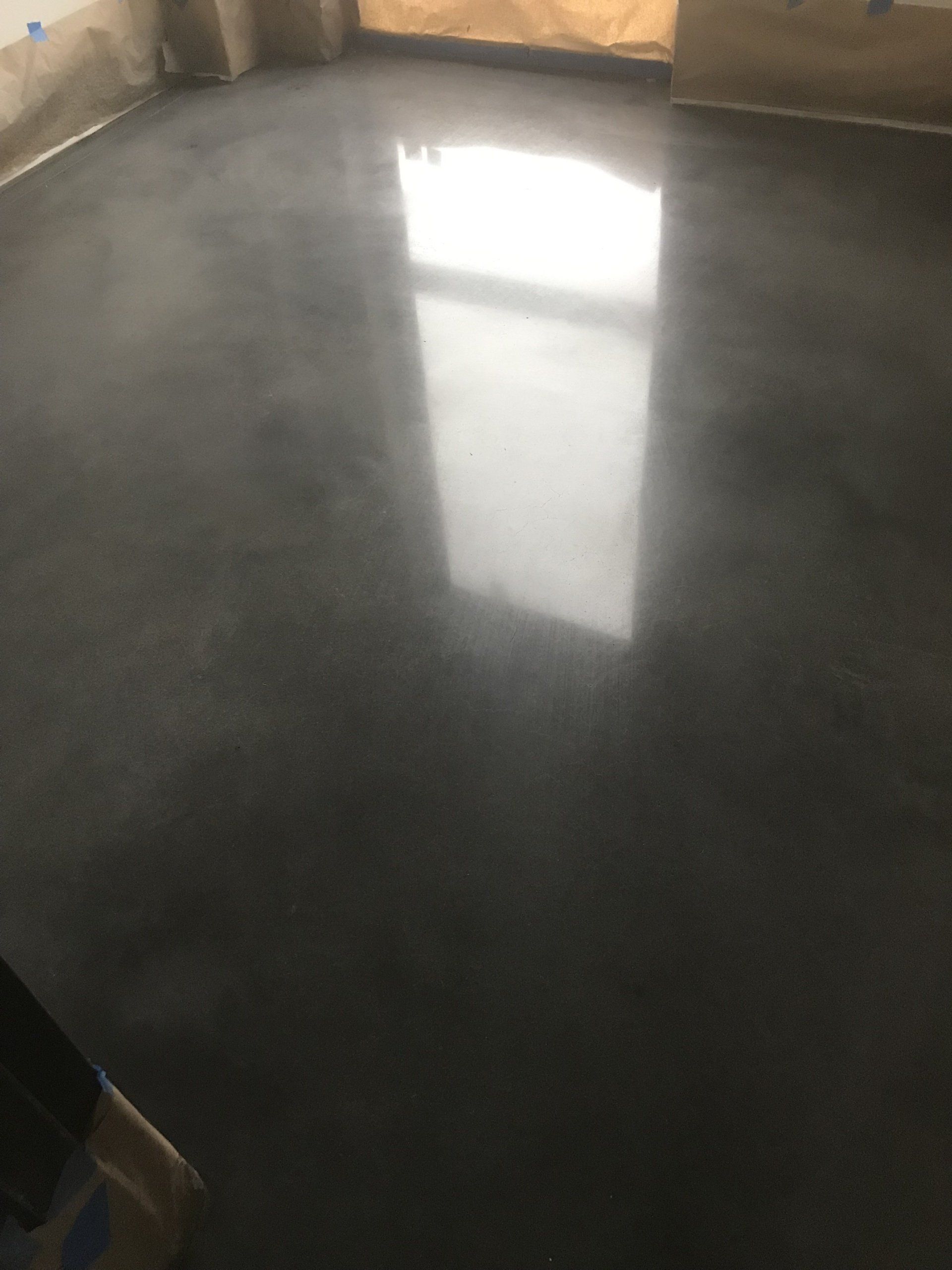

If desired, color can be added to the polished floor system. This is accomplished by the application of vibrant concrete dyes. The dye is applied before the final diamond polishing process. Consequently, it is embedded deep within the floor. The color will not flake or peel off because there is no pigmented polymer film. We offer a wide range of colors to choose from, and we can even create logos in the polished floor system. Additionally, we can use special diamond bladed saws to score concrete floors and add patterns to polished floor systems. This adds depth to the system and allows us to create truly one-of-a-kind flooring.

The grinding and polishing process can often be used to expose aggregate in concrete floors. This exposure can be moderate, resulting in a “salt and pepper finish” or it may range to the exposure of large aggregate. The exposure of aggregate is dependent on a number of factors. First, there is the issue of the aggregate’s depth within the slab. Often, because of the nature of concrete construction and job site conditions, the distribution of aggregate is not the same throughout the whole floor. Secondly, many concrete floors are not level, so the floor polishing process removes varying amounts of material across the floor. Additionally, the aggregate distribution may have been different from batch to batch when the concrete was originally placed. However, this tends to add to the uniqueness and character of polished floors. Polished floors are made of natural substances and variations within them are a natural part of their beauty and should not be considered a flaw.

We offer polished floor systems in a variety of gloss characteristics. They can range from a matte finish all the way to a high gloss finish. Matte or satin finishes are popular in warehouses and manufacturing facilities. Whereas, moderate to high gloss finishes are more frequently desired in retail and commercial buildings.

Because there is no surface coating, diamond polished concrete floors are an excellent choice when slabs are lacking properly functioning vapor barriers. The floor systems are “breathable” and allow moisture vapor to easily pass through. The completed floors are low maintenance and can be cleaned easily with water and occasionally a mild detergent. They do not require waxing and they resist scuff marks from footwear. Their low or no VOC requirements make them extremely environmentally friendly and an ideal choice for Leed projects. Polished floor systems are an excellent choice for sustainable architecture and brighten facilities by increasing light reflection. Polished concrete floors are USDA compliant and suitable for use in many food and beverage facilities. Furthermore, when dry, they meet OSHA and ADA standards for slip resistance.

We have installed polished concrete floor systems throughout Metro Atlanta as well as on numerous commercial and industrial projects throughout the U.S.A. We are available to assist you with designing your own unique polished floor and we welcome the opportunity to earn your concrete polishing business.

Call us today for a FREE quote.

770-483-6000

“You were awarded our polished concrete project of the year at our national sales meeting, for your work on the H&M in Colorado. Congrats!”

- Adam Webb, Ardex Americas

Our Facebook Feed

Contact Us

Southeast Sealing, Inc.

1222 N Main St. NW

Conyers, Georgia 30012

Tel:

770-483-6000

Conyers, Georgia 30012

Email: info@southeastsealing.com

Privacy Policy

| Do Not Share My Information

| Conditions of Use

| Notice and Take Down Policy

| Website Accessibility Policy

© 2024

The content on this website is owned by us and our licensors. Do not copy any content (including images) without our consent.