Wet Warehouse Floors in Atlanta

How To Avoid "Sweating Slab Syndrome" and the Associated Risks

Wet Concrete Floors

In metro Atlanta, as well as throughout Georgia and most of the Southeast, many warehouses and industrial properties struggle with wet concrete floors. This is frequently referred to as “sweating slab syndrome”. Wet warehouse floors and industrial floors create serious hazards for people, machinery, and investors. Wet concrete floors can lead to serious and costly slip and fall accidents. Slip and falls are the number one cause of workers compensation claims. Furthermore, they are the main cause of injury resulting in lost days from work. Forklifts, handling equipment, racking, and inventory can become damaged. We have worked on sites where wet, slippery floors have resulted in a loss of traction and the two forks of a lift truck actually penetrated an office wall. Fortunately, the occupant was not injured. In another instance, a lift truck was not able to stop and crashed into a demising wall. It shifted the wall and resulted in extensive damage to inventory in the adjacent unit. One of our clients even had a lift truck that slid out a dock door and crashed onto its side in the parking lot.

Causes of Wet Concrete Floors

There are a number of contributing factors that can come together and result in wet concrete floors or “sweaty slab syndrome”. Weather is a major factor causing condensation to occur and moisture to accumulate on concrete slabs. This most often occurs in the spring when warm moist air enters a warehouse through dock doors and other openings. Most warehouses and industrial buildings are not air conditioned. Consequently, the air inside warehouses will adjust to outside temperature rapidly while the dense thermal mass of the concrete floor is much slower to change. The result is that when warm, moist air contacts the cooler concrete floor, condensation is created, and moisture accumulates on the concrete slab’s surface. This condensation occurs when warm, moist air is cooled to the dew point. For example, if a warm front with 80 degrees Fahrenheit ambient air temperature and 80% relative humidity has air that contacts a concrete slab at 73 degrees Fahrenheit, condensation will occur.

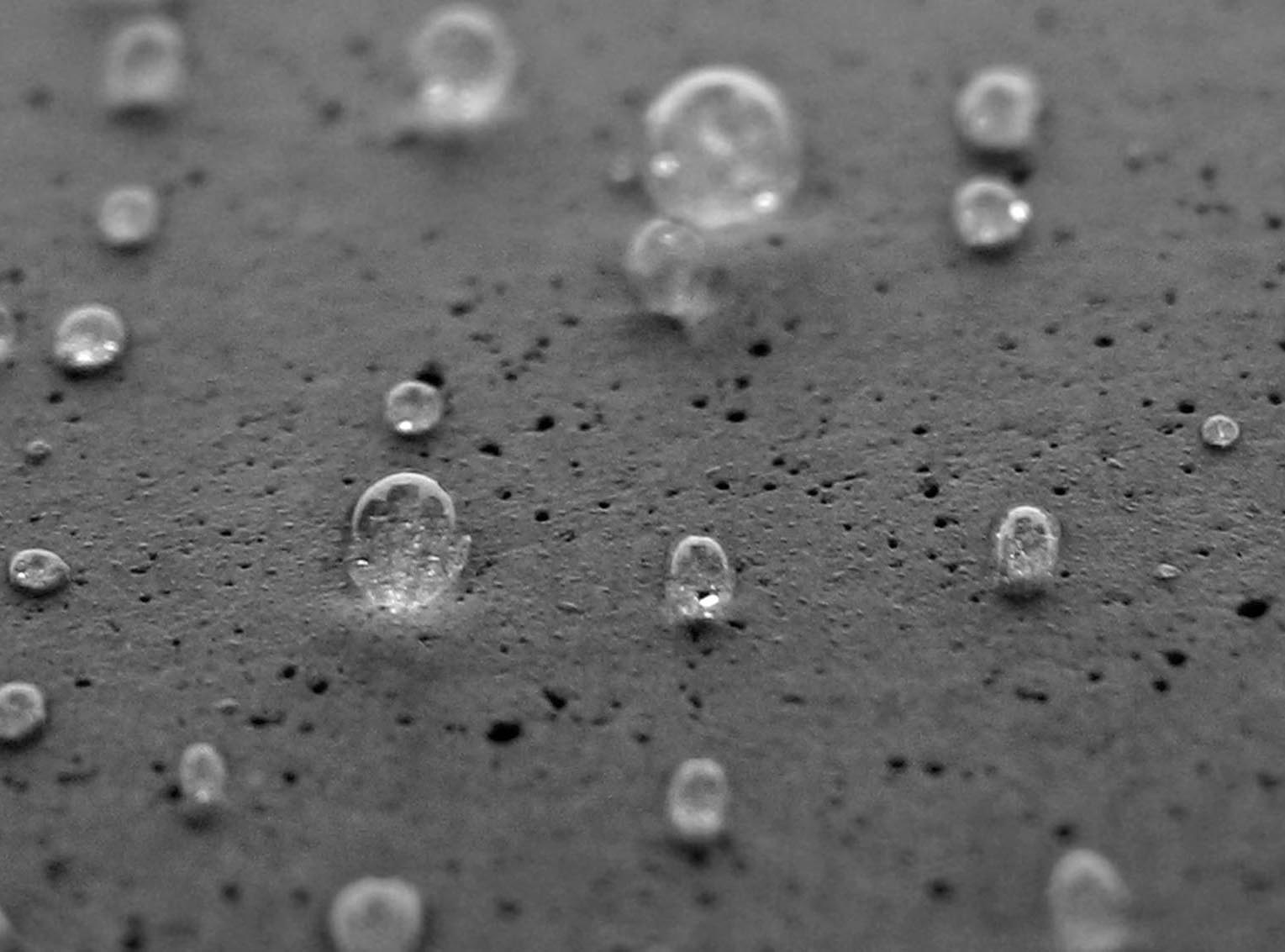

Years ago, concrete floors were finished with “wood bull floats”, resulting in a much more porous surface than modern concrete floors. As a result, in the past, porous floors were able to absorb moisture much like a sandstone coaster and provided traction. However, today most concrete floors are densely steel troweled with powerful machinery. This creates a tight surface that does not readily absorb water. Consequently, any surface moisture will “bead up” much like condensation on an enamel or metal beverage coaster.

Frequently, the accumulation of moisture on a concrete floor, or “sweaty slab syndrome”, varies significantly within a warehouse or industrial building. Often, the perimeter of the floor is dry while the rest of the building has a wet floor. This frequently occurs in modern “tilt up” buildings. “Tilt up” construction requires the concrete floor of the building's perimeter to be poured and finished at a later date than the rest of the building's floor. Frequently, it is not trowel finished as densely as the rest of the floor and has a more porous surface. This porous surface more readily absorbs moisture and stays drier than the rest of the slab.

Vapor barriers play a huge role in preventing or minimizing “sweaty slab syndrome” or wet concrete floors. Vapor barriers are plastic membranes placed on the ground before concrete floors are poured and finished. They are intended to prevent or reduce the upward transmission of moisture vapor through a concrete slab.

It may seem counterintuitive that moisture could rise up and pass through a thick concrete floor. Yet it does, and it can be a major problem. Concrete is actually very porous and, when magnified, tiny capillaries are revealed that run vertically to the floor’s surface. Moisture vapor in the soil has a tendency to migrate upward through concrete slabs when a properly functioning vapor barrier is not present. Variances in atmospheric pressure can be a significant factor in the upward rise of moisture vapor. As this moisture vapor migrates to the surface of the concrete floor it carries with it mineral salts and other impurities within the concrete slab. When the moisture evaporates, the impurities are left on the surface and result in a white colored residue known as efflorescence. Unfortunately, this is not just a cosmetic problem. Efflorescence, or salt deposits are hygroscopic in nature. Consequently, they absorb and hold on to moisture in the air. Thus, a lack of a vapor barrier can significantly contribute to wet concrete floors and sweaty slab syndrome. Routine cleaning of the floor with a floor scrubber using water and detergent can help remove efflorescence and reduce moisture accumulation.

Many buildings in metro Atlanta only have properly functioning vapor barriers under part of the slab. This can occur when the vapor barrier is damaged during construction before or during the placement of the concrete floor. The vapor barrier can be punctured, accidently or on purpose.

You might ask why would someone puncture the vapor

barrier on purpose during construction?

The answer is that they want to leave work earlier than they could

otherwise by expediting the removal of “bleed water” from the surface.

When a cement floor is poured, water is added to the mix to make it pliable. This water is often called the “water of convenience”. As the aggregate and other particles of the mix settle to the bottom of freshly placed concrete, the “water of convenience” or excess mixing water is pushed to the top of new slab. This water, which results during concrete placement is commonly known as “bleed water”. A very basic and fundamental rule of concrete construction is that a newly placed slab should never be steel troweled or “floated” before the bleed water evaporates from the surface. When fresh concrete is troweled or finished while bleed water is still on the surface, the new floor is likely to have a variety of problems such as diminished abrasion resistance, cracking, dusting, and lower density. Rather than wait for the water to evaporate, workers sometimes use steel rods to puncture the vapor barrier and allow the water to sink into the soil below the slab. Unfortunately, in such instances the vapor barrier has been permanently damaged.

Additionally, some contractors have a standard practice of only placing vapor barriers below the slab in areas where offices are anticipated to be constructed. Often, with new spec buildings, the vapor barriers are only placed from the “store front” to the first column back. This occurs frequently throughout Metro Atlanta and can lead to major moisture related problems. The high costs of the resulting industrial accidents and remediation costs generally far exceed the dollar savings of omitting vapor barriers.

Dealing with moisture issues on warehouse floors is more difficult than dealing with moisture in office areas. In finished offices spaces, HVAC systems generally prevent moisture from accumulating on the surface of the flooring. However, moisture vapor may rise up through a slab without a properly functioning vapor barrier and accumulate under file cabinets and furniture or cause serious issues under flooring such as VCT and linoleum. These moisture issues are usually best addressed with negative side moisture remediation barriers.

However, with warehouses it is often cost prohibitive to install negative side remediation floor systems or air conditioners. Large fans circulating air can help to reduce temperature differences at the slab surface. However, because of racking and inventory, it is often difficult to get adequate air movement along the slab. None-the-less, horizontal air movement provided by fans across the surface of the slab can be very effective in controlling moisture accumulation on floors. This is similar to air flow around a moving car preventing dew from accumulating. However, when the car is parked and its temperature reaches the dew point moisture will bead up on the vehicle.

Southeast Sealing, Inc. helps our clients manage sweating slab syndrome. We do this by installing the BYAL Floor System. The BYAL floor system was developed to help manage “Sweating floor syndrome” by improving traction and minimizing the accumulation of surface moisture. This is achieved by mechanically abrading the slab surface and applying a unique proprietary penetrating water based solution that chemically reacts within the concrete slab.

The combination of increased surface texture and the application of CCS 3300 results in improved safety and lower maintenance costs. The chances of slip and falls are reduced. Additionally, equipment such as forklifts and personnel carts,= operate more safely and reliably.

Modern concrete slabs are usually steel troweled with a smooth and dense surface. The BYAL system uses mechanical abrasion to add texture and porosity. This increases traction. Additionally, surface moisture resulting from condensation is more readily absorbed by the concrete. The abrading process also serves the purpose of removing efflorescence and surface contaminants such as soluble salts and dirt. CCS 3300 is designed to penetrate deep within the concrete slab. By means of chemical reaction it becomes an integral part of the concrete itself. While remaining “breathable”, it fills capillaries and tiny pores, thus slowing effervescence and the migration of moisture and mineral salts to the surface. Salt deposits are undesirable because they attract and retain moisture from the atmosphere as well as from within the slab itself.

Routine cleaning and maintenance of the floors is important to reduce the accumulation of efflorescence. Also, on occasions when moisture does accumulate, a wet, clean floor is much less slippery than a wet, dirty floor.